We Understand Your Pain. We've Lived It

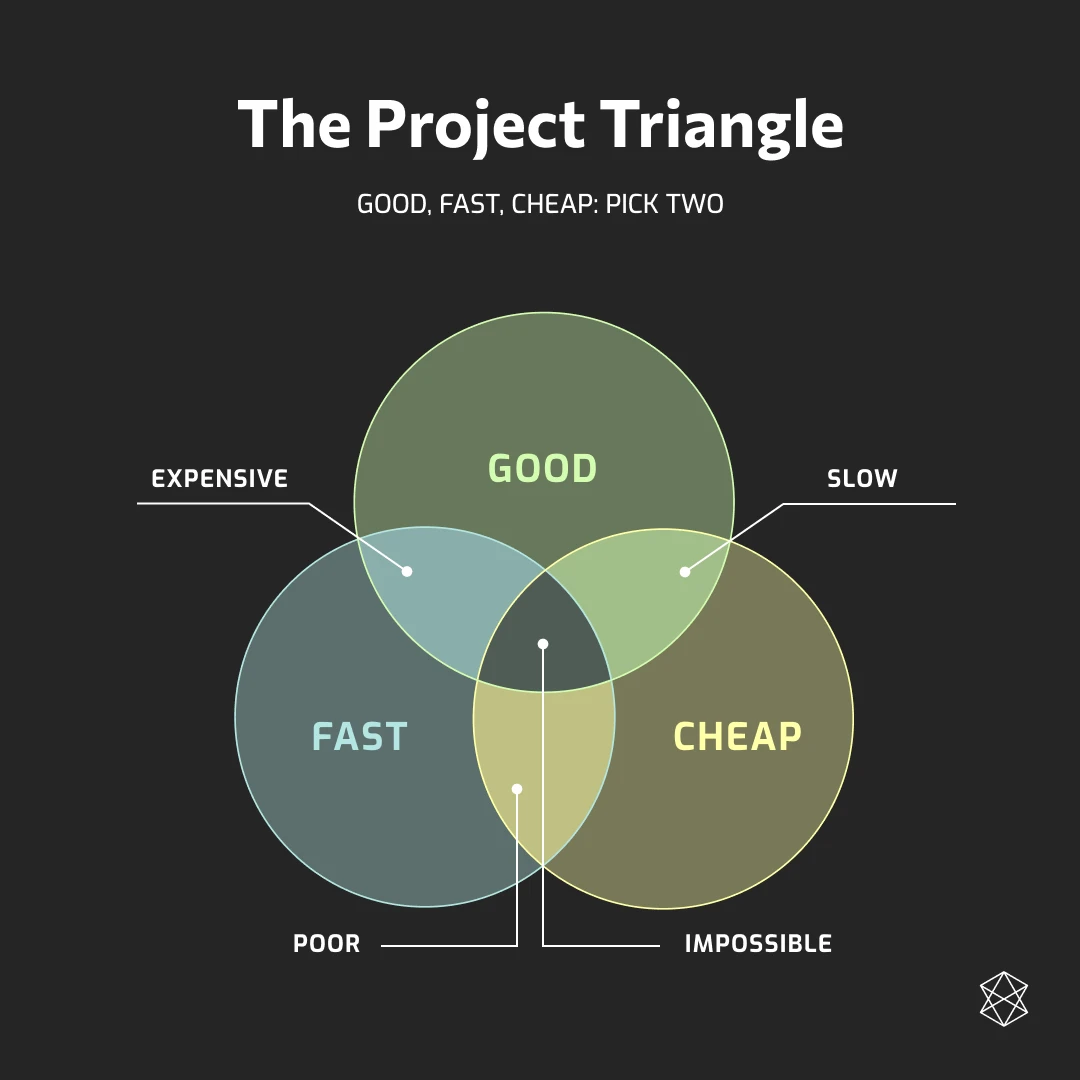

You've seen the statistics: 70% of digital transformation initiatives fail. But the failure isn't in the technology - it's in the human resistance, political battles, and fear of breaking what's already working. Every manufacturing leader faces the same brutal reality: you're expected to transform operations while keeping production running, managing competing priorities, and navigating organizational politics.

We don't just solve technical problems - we solve human problems with technical solutions. We won't sell you a massive transformation project. We'll help you solve one real problem that unlocks the next opportunity.